Page 1 of 13

Greg D's Traditional Build of a 1964 F 250

Posted: April 17, 2010, 8:12 am

by Greg D

Well, actually I'll just fix a few things first. I am going to start on it today so I thought a build thread was in order.

Plans are;

pull the 292 and freshen it up

reinstall with my T-5

cut it down to a short

lower it with F100 axles

will install the tires & wheels from the 62 (they need to not just be sitting there)

repaint it - no not beige

I'll will eventually do more to it but this is the list for this year. I plan to drive this truck to SS.

Here is the purchase announcement thread rather than reposting it all here.http://fordtruk.com/forums/viewtopic.php?t=15847

Posted: April 18, 2010, 2:39 pm

by 62bigwindow

If it is not too much trouble i would like to see some pics of the engine mounts.I am putting a y-block in my uni and plan to use car mount as opposed to the truck mounts.With the aod i am using i am worried that there will be too long of a span between mounts.Afraid it will put too much stress on bell housing area.

Posted: April 18, 2010, 8:03 pm

by Greg D

Posted: April 19, 2010, 8:32 pm

by Greg D

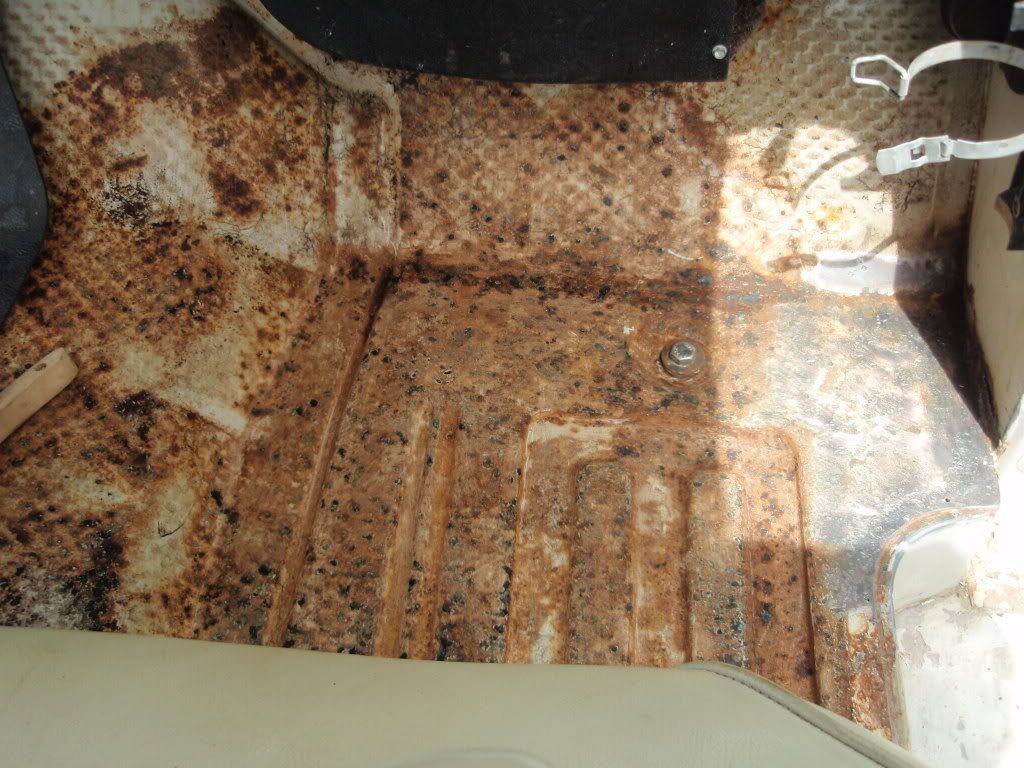

Cleaned up the drivers side floor today after work.

Considering the condition of this truck it would be shame not to weld a small patch here. This right under the brake pedal where the mat was worn through.

Patch will be about the size of a business card is all. I am out of .030 flux core so I'll have to pick up a roll to do it. Seeings as I can't get it perfectly clean without digging into the metal more than I want to and and I can't get to the back side flux core is the way to go here.

I'll be a really lucky guy if this is the worst patch I ever do again, lol.

Posted: April 19, 2010, 10:21 pm

by Paranoid!

Not bad at all....

I allways find myself holding my breath when looking under them mats for the first time....

Posted: April 20, 2010, 6:30 pm

by Greg D

I examined it REAL close underneath - pretty much knew what I would find.

Tonight is a secondary project to this truck - swapping the fuel pump in the van so I can put the 64 in the drive. If I don't have to keep it movable so I can put it back across the street I can get alot more done.

Supposed to get a couple days of rain - I'll start getting a few things together for it for the next round.

Still working on picking colors - have a few ideas but haven't settled on one.

I was originally going to be a semi flat black with some metallic custom paint (secret, lol), see alot of cars & trucks done like that anymore - it's still on the table though. I'll need to pick something before I fix the roof - I'll want to get the color around the windshield frame before the glass goes back in so I don't have to pull it again for paint.

Posted: April 24, 2010, 12:57 pm

by rwhistles

OK so where's the pic of the whole truck before you molested it? Did I miss them in another thread?

Posted: April 24, 2010, 6:31 pm

by Alan Mclennan

Greg D wrote:Cleaned up the drivers side floor today after work.

Considering the condition of this truck it would be shame not to weld a small patch here. This right under the brake pedal where the mat was worn through.

Patch will be about the size of a business card is all. I am out of .030 flux core so I'll have to pick up a roll to do it. Seeings as I can't get it perfectly clean without digging into the metal more than I want to and and I can't get to the back side flux core is the way to go here.

I'll be a really lucky guy if this is the worst patch I ever do again, lol.

Greg, just as a suggestion, why don't you just clean the area up good and put a layer of Bronze weld over the area, then coat with Por 15. It`s not a structural location!, Just saying!

Posted: April 25, 2010, 4:12 am

by blackagatha

wow I wish the floor in Aggie was that good.... She had CARPET...

so, alan, what is this Bronze Weld?

Posted: April 25, 2010, 9:49 am

by Greg D

Robert,

the link in the first post will take you to pics of it.

Alan - Bronze weld?

Posted: April 25, 2010, 10:00 am

by slick4x4

i think what Alan is saying is just to take a torch and some brazing rod &

fill in the holes with brass...

then put the POR over the top and you wont even notice.

Posted: April 25, 2010, 11:08 am

by rwhistles

Wow greg I musta been asleep when you posted that one don't know how I missed that.Looks like you got a winner there. congrats

Posted: April 25, 2010, 6:34 pm

by Alan Mclennan

Pat you got it in one!, they are only small holes!, so cutting out the section some times is a bit of over kill!. I think a lot of pin holes can be over come this way, just watch the heat!

Posted: April 26, 2010, 8:02 pm

by Greg D

I don't have an Ox/Acetylene set up. Maybe could grab one of those small ones just for this though - I'll check into one.

I did get some cleaning & prepping done over the weekend. Got some paint I need ordered.

I also managed to pic the base color for the paint job. I have had the scheme in my head for awhile.

Been wet & rainy since Saturday so not much since then.

Next decent day the bottom of the cab starts getting POR.

I found a new similar Product at the paint store that is a much better price - $37 vs $50 a quart. If these guys carry it - it's good.

Posted: April 26, 2010, 10:17 pm

by MadMaxetc

Greg. You should be able to get by with JB Weld or POR Puddy or something like that. Those are small holes.

I would use JB Weld and put a small peice of 22g steel over the wet JB Weld and and "Glue" it in place. Then you wouldn't need to worry about heat.

Then POR the floor.

Posted: April 27, 2010, 3:21 am

by Paranoid!

Yeah!!!

JB Weld that som'bit@h Greg!!!....

Posted: April 27, 2010, 10:05 am

by Greg D

That's a pretty good idea. I could also use it as a putty to fill some of the bigger pits. After the bottom is POR'd I should have it sealed real well then.

Posted: April 27, 2010, 8:49 pm

by bird55

I'm envious of those that have welders and can use 'em but what I use on small stuff like that is 3M Structural adhesive And sometimes a sheetmetal patch if needed. Gotta clean up all the metal prep as usual but it works super fast and doesn't dry glass hard, but has a slight flex feel to it. Then, you can also grind and sand it, paint it. Someday I'll try to get pics of the process.

Posted: April 27, 2010, 9:00 pm

by Rusty 63

My 2c would be to POR15 the rust before you putty it up.

Posted: April 28, 2010, 11:26 am

by ebentraywick

looks great dude more pics less talk lol jk