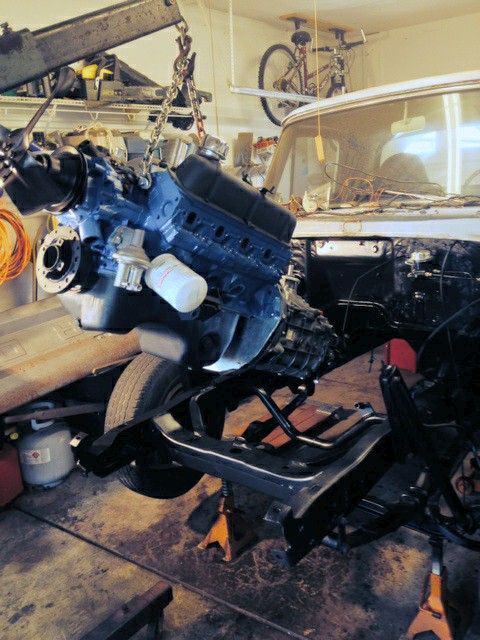

Since this is on my sons dollar as a high school senior working at a restaurant we ended up going with a good streetable hydraulic non-roller cam he can upgrade later as funds allow later. The Craig's list motor we snagged ended up not being as advertised when we tore it apart. Shock!! While it is a roller block the roller parts were long gone. An easy fix down the road. We were fortunate to snag a nice set of GT40 3 bar heads for it ready to roll. So toghether it went after the machine shop with my son learning the ropes on engine assembly.

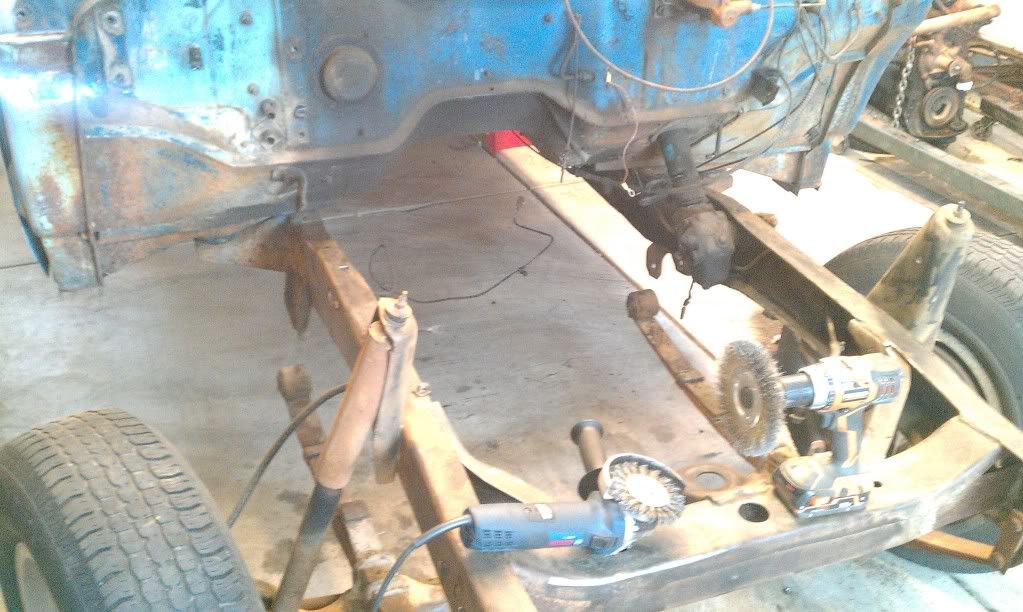

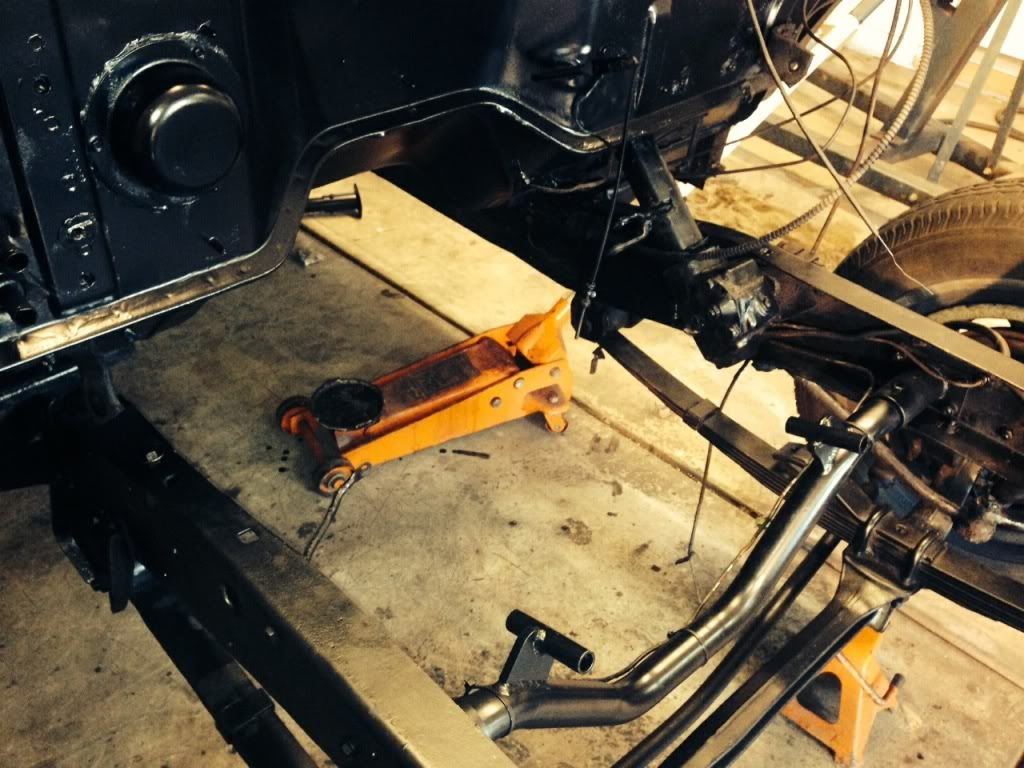

We did get some new stainless OBX headers in for a mid 70's F100 that I was pleasantly shocked with the heavy duty flanges on.

Since the original motor was a 2 barrel we got a got a good deal on a used Performer RPM and carb we rebuilt to top the motor off. A trial fit of the headers confirmed my suspicion of our need for 1" header bolts rather than the traditional 3/4" length due to the 3/8" thick flanges on the headers. Otherwise I think they are going to be good.

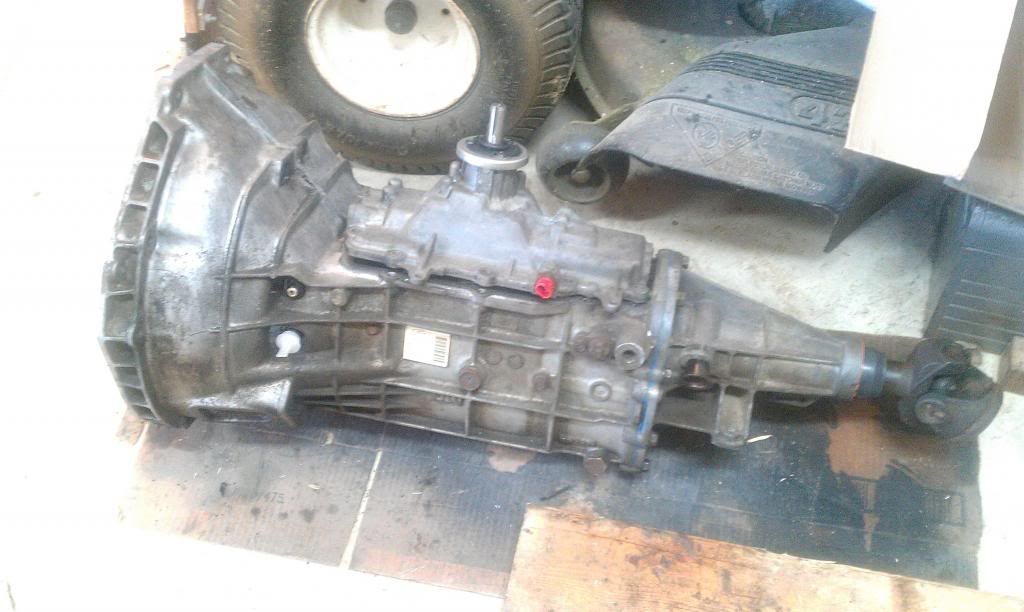

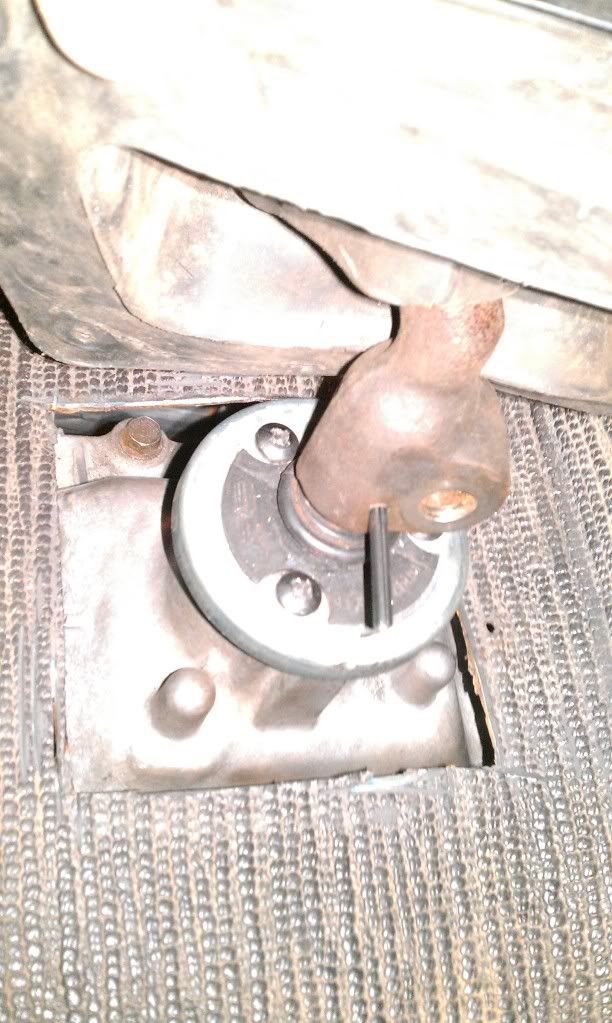

The M5R2 we got for $125 turned out to be a 1994 that runs the Speedo off the rear differential meaning it had no provisions for mechanical or electronic Speedo on the tranny of any kind. Everything I read said a new tail housing and tail shaft for a speedo gear were required. But since it had the casting for a Speedo hookup I decided to see what I could come do with a little gargage machine work. The hole is just a recess in the casting that is a dead end.

I chucked up the tail housing in the drill press with a 7/8 bit and drilled 2" deep on the outer diameter.

Then I drilled the center deep enough to accept the tip of the Speedo gear to 13/64 diameter which is a hair over the 3/16 gear tip diameter.

Now for the shaft. It wasn't machined for the driven gear so I marked where the gear should go and marked it for a snap ring groove on each side. My phone went dead so unfortunately I didn't get any pics. This is where I left my precision past behind for a bit of gargage floor bubbafication. I took a dremmel with a fiber cutting wheel and held it 90 degrees to the shaft and turned the shaft by hand while holding the wheel where I wanted each groove until it was deep enough for the retaining ring. I then ground a groove the same length of the rounded recess inside the Speedo driven gear and placed a roll pin in the groove. Then I slid the driven gear over the roll pin and put in the second snap ring to hold it all on place. The roll pin is jammed between the snap ring and the gear to keep it from getting out. Unfortunately I sealed the tail housing on and blotted it down befor my camera got back up to charge but hopefully you get the idea.

The good news is when I slid the Speedo cable in it feels like it should and when I turn the tail shaft the speedometer cable turns! Hopefully it will work. If it doesn't that's what my son gets for free dad labor.

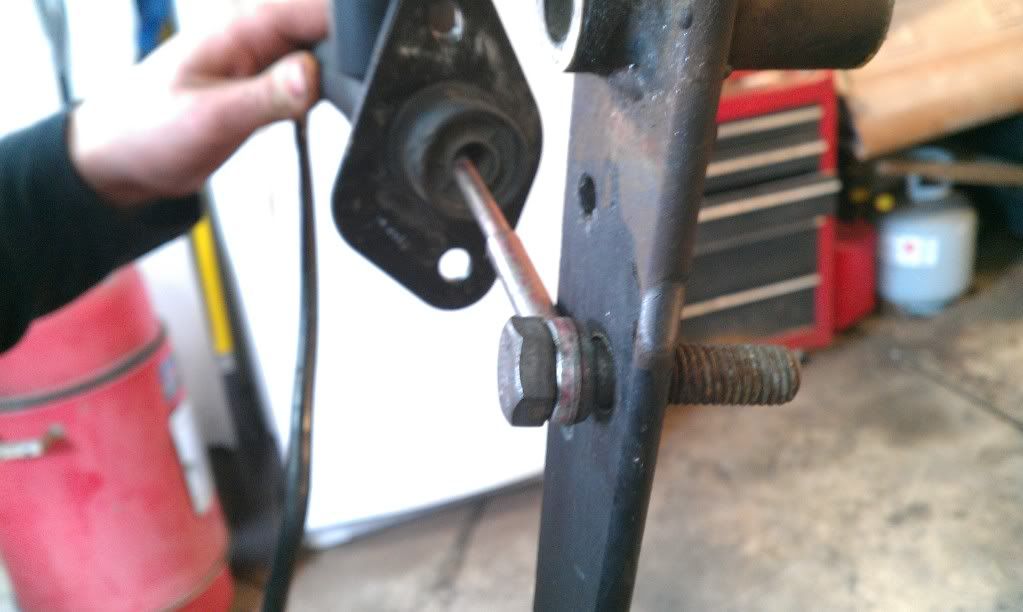

We put in a new front and rear seal, slave cylinder, and shift repair and seal kit while we have it out. My biggest strange challenge now is simply finding an actual shift lever for it. Hopefully with a few warm days ahead we can hit the junk yards and find one.