**I will not know for awhile how this will work as I'm a ways away from driving my truck.**

After seeing the sway bars that Don Miller purchased for his '65, I thought this was what I was looking for. This is also how the sway bar is installed on my Jeep Wrangler.

I have everything needed to do Skip's Ranger version, but since installing the rack & pinion, wasn't sure I would have the room on the axle for the sway bar as well.

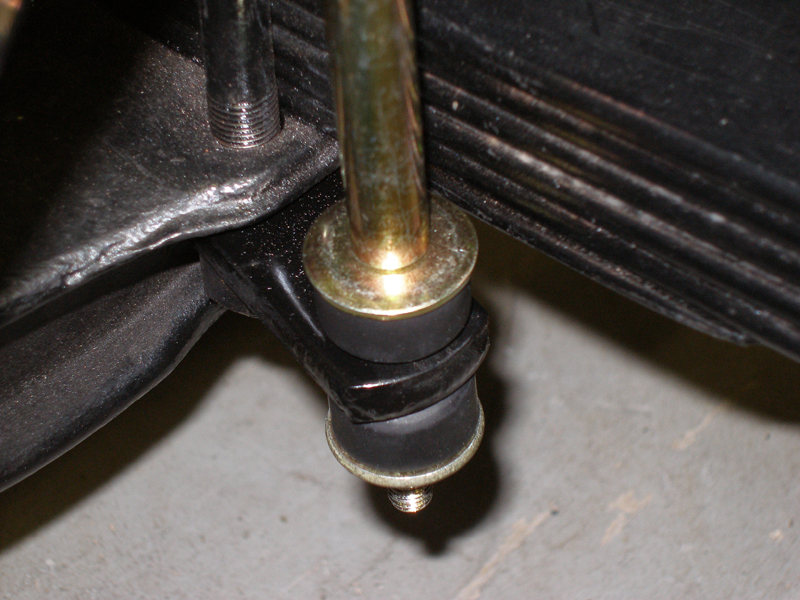

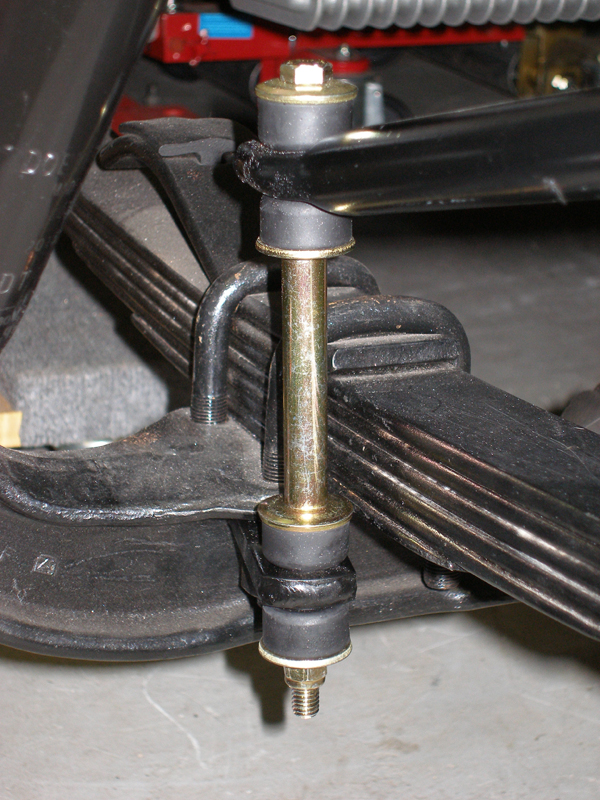

Sway bar is from a 67-72 F100 ($139-Summit Racing/Aadco), but fits our frame width perfectly. I bought 4 spring shackle links from Northern Tool to attach the drop links to ($8 total). I tig welded 2 together on each side to give me a 3/8" pad and painted them with chassis paint.

One end attaches to the bottom spring u-bolt and the other end holds the droplink. In order to do this correctly and keep the end of the sway bar level with the lower droplink attachment, I had to buy longer links. I went with 8.5", Grade 5 zinc plated bolts and longer spacer but used the original polyurethane bushings.

Here is completed installation: