Hope this helps!

Russ

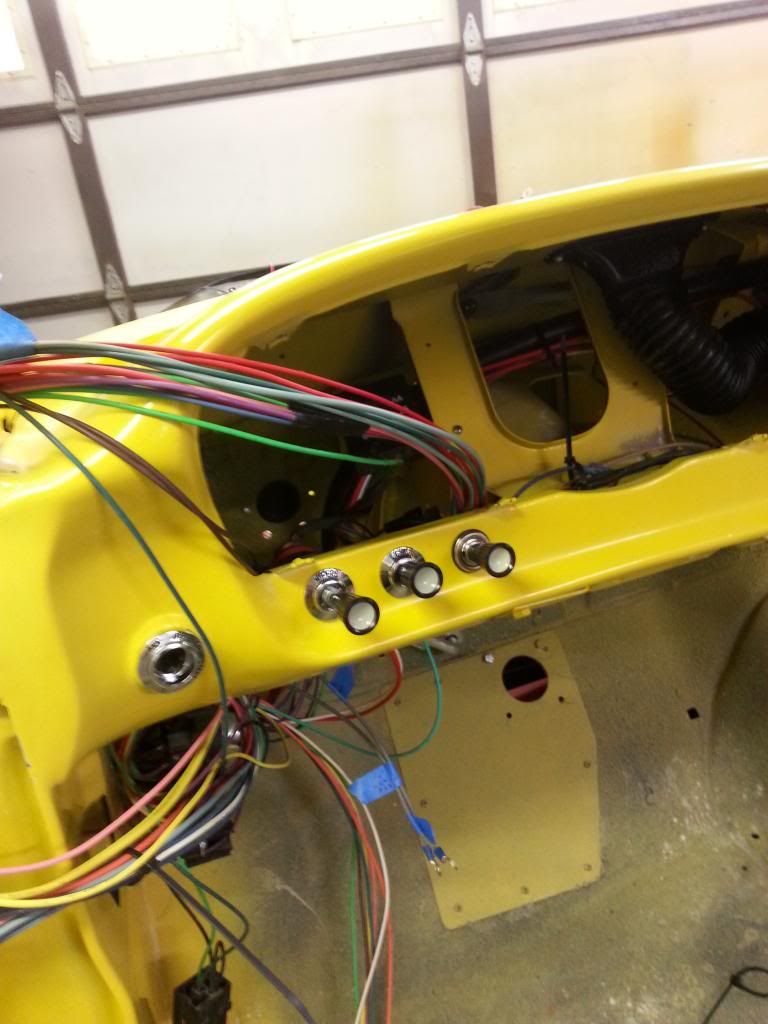

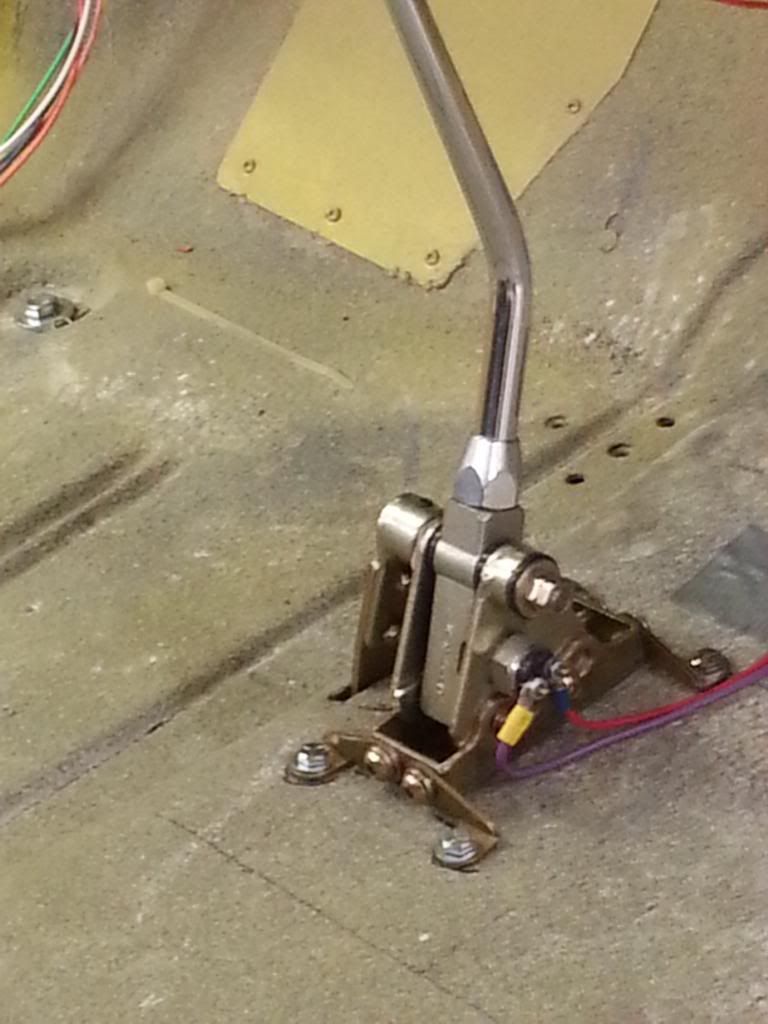

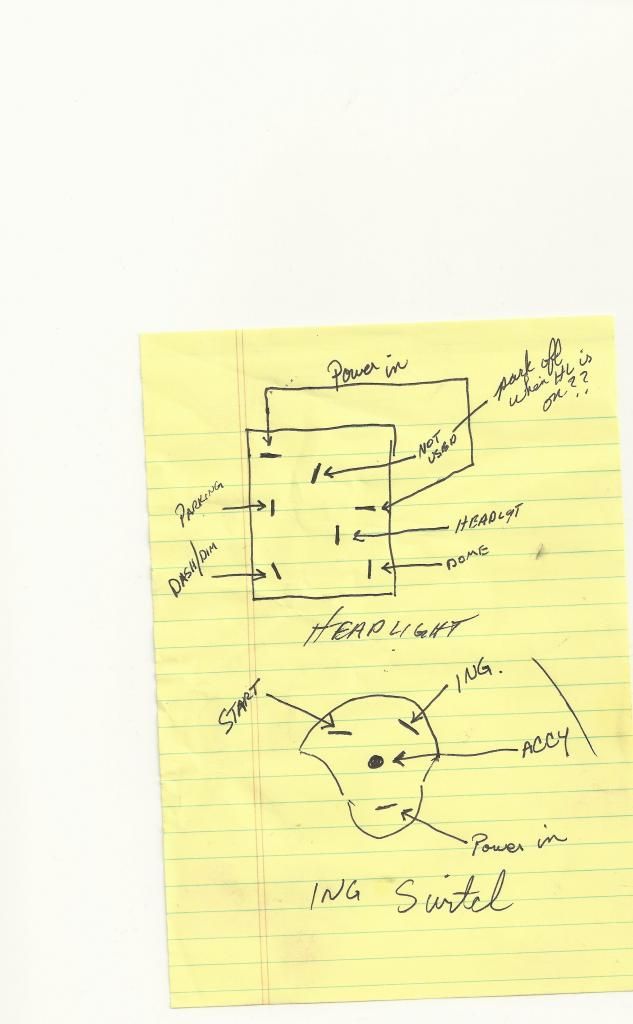

Uncle Skip wrote:Got started in earnest with the wiring today, A/C power hooked up, wiper motor switch installed, and the ignition switch in. The original light switch change over to the EZ wire harness is causing me to have gas. Can't decipher the Ford to GM scheme. Any suggestions would be appreciated.

The big issue is the shocks on the lowered rear end. I need a shock that has about a 15" OAL and a 7" compression/ extension.

Here are photos of what we have to work with. I can gain about 1" with the original upper shock mounts by rotating them up but I can't go much above the frame because of interference with the bottom of the bed wood. I'm open to most anything here.

Help me out.

Hey Russ, probably a dumb question, but do you know if the dome blade is 12+ or a negative connection?loosrp wrote:Here you go Skip, I also used the EZ Wire Harness

Hope this helps!

Russ